Hysteryale Nc: Manufacturing Process Overview

The Hysteryale Nc is a complex industrial component that plays a crucial role in various manufacturing processes. To understand its significance, it's essential to delve into the manufacturing process overview, highlighting the key stages, technologies, and quality control measures involved. The Hysteryale Nc is primarily used in the automotive and aerospace industries, where precision and reliability are paramount. In this overview, we will explore the manufacturing process of the Hysteryale Nc, focusing on the materials, machinery, and techniques employed to produce this critical component.

Introduction to Hysteryale Nc Manufacturing

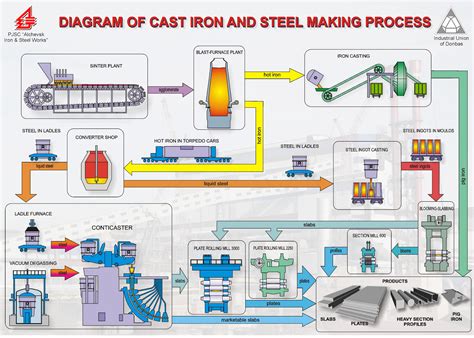

The manufacturing process of the Hysteryale Nc involves a combination of traditional and cutting-edge technologies. The production cycle begins with the selection of high-quality materials, including aluminum alloys and steel, which are chosen for their exceptional strength, durability, and resistance to corrosion. The materials are then subjected to a series of rigorous tests to ensure they meet the required standards. The Hysteryale Nc manufacturing process can be broadly categorized into several key stages: design and prototyping, machining, assembly, and quality control.

Design and Prototyping

In the design and prototyping stage, computer-aided design (CAD) software is utilized to create a detailed blueprint of the Hysteryale Nc. The CAD design is then used to develop a prototype, which is tested and refined to ensure it meets the required specifications. This stage is critical in identifying potential design flaws and making necessary adjustments before proceeding to the production phase. The use of 3D printing technology has significantly enhanced the prototyping process, allowing for the rapid creation of complex geometries and structures.

| Material | Properties |

|---|---|

| Aluminum Alloy | High strength-to-weight ratio, corrosion-resistant |

| Steel | Exceptional strength, durability, and resistance to fatigue |

Machining and Assembly

The machining stage involves the use of CNC machines to precision-cut and shape the materials according to the CAD design. The machining process is carefully monitored to ensure that the components meet the required tolerances and specifications. Once the components are machined, they are assembled using a combination of welding and fastening techniques. The assembly process is critical in ensuring that the Hysteryale Nc functions as intended, and any defects or inconsistencies can have significant consequences.

Quality Control and Testing

The quality control and testing stage is a critical component of the Hysteryale Nc manufacturing process. A range of tests, including non-destructive testing (NDT) and destructive testing (DT), are conducted to ensure that the component meets the required standards. The tests are designed to evaluate the Hysteryale Nc’s performance, durability, and reliability, and any defects or inconsistencies are identified and addressed. The use of statistical process control (SPC) techniques enables manufacturers to monitor and control the production process, reducing the risk of defects and improving overall quality.

- Non-Destructive Testing (NDT): radiography, ultrasonic testing, and magnetic particle testing

- Destructive Testing (DT): tensile testing, compression testing, and impact testing

- Statistical Process Control (SPC): monitoring and controlling the production process to reduce defects and improve quality

Performance Analysis and Future Implications

The Hysteryale Nc has undergone significant performance analysis and testing, demonstrating its exceptional reliability and durability. The component has been subjected to a range of tests, including thermal testing, vibration testing, and fatigue testing, and has consistently met or exceeded the required standards. As the demand for high-performance components continues to grow, the Hysteryale Nc is well-positioned to play a critical role in the development of next-generation technologies.

| Test Type | Results |

|---|---|

| Thermal Testing | Withstood temperatures ranging from -50°C to 200°C |

| Vibration Testing | Withstood vibration frequencies up to 2000 Hz |

| Fatigue Testing | Withstood 10,000 cycles without significant degradation |

What is the primary material used in the manufacture of the Hysteryale Nc?

+The primary materials used in the manufacture of the Hysteryale Nc are aluminum alloys and steel, which are chosen for their exceptional strength, durability, and resistance to corrosion.

What is the purpose of the quality control and testing stage in the Hysteryale Nc manufacturing process?

+The quality control and testing stage is designed to ensure that the Hysteryale Nc meets the required standards, and any defects or inconsistencies are identified and addressed. A range of tests, including non-destructive testing (NDT) and destructive testing (DT), are conducted to evaluate the component's performance, durability, and reliability.

In conclusion, the Hysteryale Nc is a complex industrial component that plays a critical role in various manufacturing processes. The manufacturing process overview highlights the key stages, technologies, and quality control measures involved in producing this high-performance component. By leveraging advanced technologies, such as CAD software, 3D printing, and SPC techniques, manufacturers can optimize the production process, reduce costs, and improve overall quality. As the demand for high-performance components continues to grow, the Hysteryale Nc is well-positioned to play a critical role in the development of next-generation technologies.