Green Beans Coffee Roasting Guide

Green coffee beans are the raw material used to produce the various types of coffee that are consumed globally. The process of transforming these green beans into the flavorful beverage involves roasting, which is a critical step in bringing out the unique characteristics of each coffee variety. The art of coffee roasting is complex, requiring a deep understanding of the chemical and physical changes that occur during the roasting process. This guide provides an in-depth look at the green beans coffee roasting process, covering the basics, the roasting stages, and the techniques involved in producing high-quality roasted coffee.

Introduction to Green Coffee Beans

Green coffee beans are harvested from the coffee plant, Coffea arabica or Coffea canephora (Robusta), and then processed to remove the outer skin and pulp. The resulting beans are green, dense, and have a grassy or herbal aroma. The quality and characteristics of the green beans depend on factors such as the coffee variety, growing conditions, altitude, soil type, and processing methods. High-quality green coffee beans are essential for producing exceptional roasted coffee, as they provide the foundation for the development of the desired flavor profile.

Green Coffee Bean Processing Methods

There are several processing methods used to convert coffee cherries into green coffee beans, including the natural (dry), washed (wet), and honey (pulped natural) methods. Each method affects the flavor and quality of the green beans, with the natural method often producing fruitier and more full-bodied coffee, while the washed method results in cleaner and more acidic coffee. The choice of processing method depends on the coffee producer’s preferences, the climate, and the available resources. Understanding the processing methods is crucial for coffee roasters, as it helps them to predict the potential flavor profile of the green beans and make informed decisions about the roasting process.

| Processing Method | Characteristics |

|---|---|

| Natural (Dry) | Fruity, full-bodied, and sweet |

| Washed (Wet) | Clean, acidic, and tea-like |

| Honey (Pulped Natural) | Balanced, sweet, and fruity |

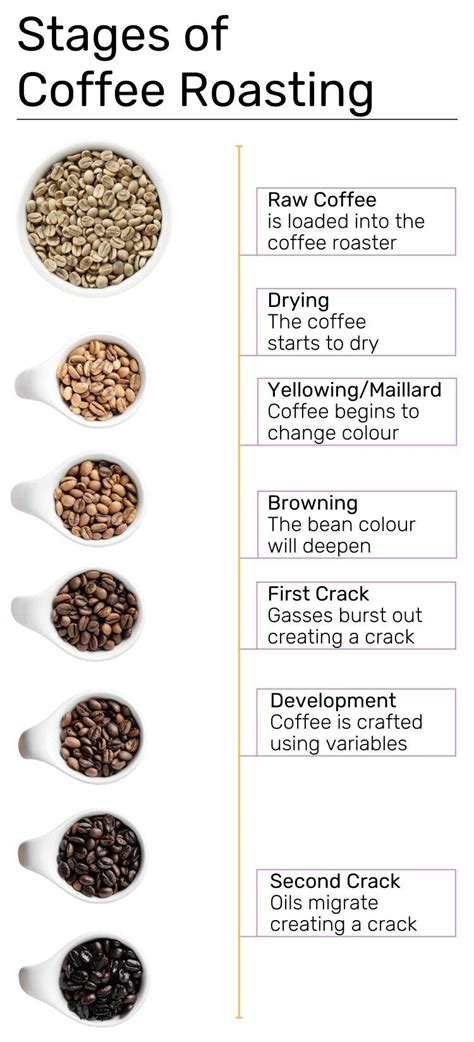

The Roasting Process

Coffee roasting involves heating the green coffee beans to high temperatures, typically between 350°F and 450°F (175°C and 230°C), to bring out the desired flavors and aromas. The roasting process can be divided into several stages, including drying, expansion, and pyrolysis. Drying occurs when the beans are first heated, causing the moisture content to decrease. Expansion occurs as the beans absorb heat and expand in size, leading to the formation of the desired flavor compounds. Pyrolysis is the final stage, where the beans undergo a series of complex chemical reactions, resulting in the development of the coffee’s color, flavor, and aroma.

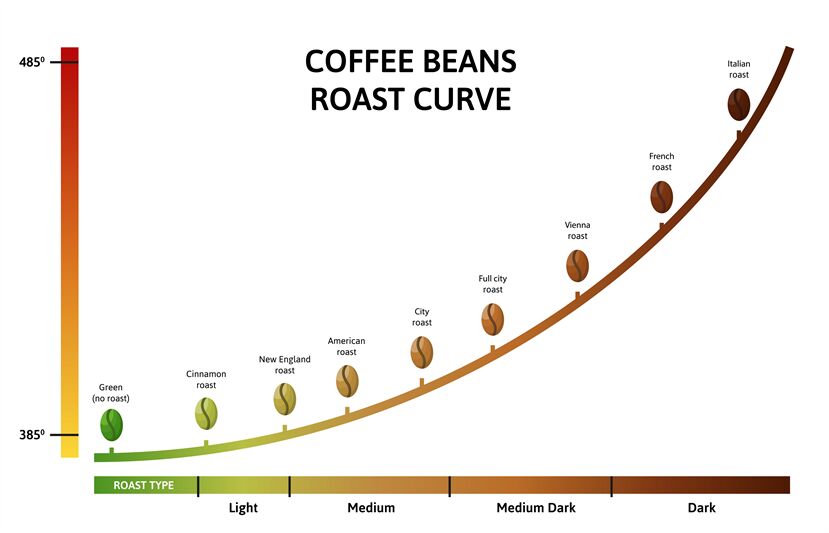

Roast Levels

Coffee roast levels are categorized based on the degree of roasting, with lighter roasts having more acidity and fruitier flavors, while darker roasts have a richer, more bitter flavor. The most common roast levels include Light, Medium, Medium-Dark, Dark, and Espresso. Light roasts are roasted to an internal temperature of around 400°F (200°C), while Espresso roasts are roasted to an internal temperature of around 450°F (230°C). The choice of roast level depends on personal preference, as well as the intended use of the coffee, such as brewing, espresso, or cold brew.

| Roast Level | Internal Temperature | Characteristics |

|---|---|---|

| Light | 400°F (200°C) | Acidic, fruity, and tea-like |

| Medium | 420°F (220°C) | Balanced, sweet, and nuanced |

| Medium-Dark | 430°F (220°C) | Rich, full-bodied, and slightly sweet |

| Dark | 440°F (225°C) | Bitter, smoky, and intense |

| Espresso | 450°F (230°C) | Very dark, bitter, and intense |

Coffee Roasting Techniques

Coffee roasting techniques involve the application of heat, air, and time to achieve the desired roast level and flavor profile. There are several roasting techniques, including batch roasting, continuous roasting, and drum roasting. Batch roasting involves roasting small batches of coffee beans in a rotating drum, allowing for greater control over the roasting process. Continuous roasting involves roasting coffee beans in a continuous flow, using a conveyor belt or pneumatic system. Drum roasting involves roasting coffee beans in a rotating drum, using a combination of hot air and radiant heat.

Coffee Roasting Equipment

Coffee roasting equipment includes drum roasters, batch roasters, and continuous roasters. Each type of equipment has its advantages and disadvantages, depending on the scale of production, the type of coffee being roasted, and the desired roast level. Drum roasters are commonly used for small-batch roasting, while continuous roasters are used for large-scale commercial roasting. Batch roasters are versatile and can be used for a variety of roast levels and coffee types.

- Drum Roasters: Suitable for small-batch roasting, offering greater control over the roasting process

- Batch Roasters: Versatile and suitable for a variety of roast levels and coffee types

- Continuous Roasters: Suitable for large-scale commercial roasting, offering high efficiency and consistency

Quality Control and Cupping

Quality control is essential in coffee roasting, involving the evaluation of the green coffee beans, the roasting process, and the final roasted coffee. Cupping is a critical step in quality control, involving the sensory evaluation of the coffee’s flavor, aroma, and body. Cupping involves brewing the coffee using a standardized method, such as the SCAA (Specialty Coffee Association of America) cupping protocol, and evaluating the coffee’s characteristics using a scorecard. Cupping helps coffee roasters to identify defects, such as bitterness, acidity, or flavor imbalances, and make adjustments to the roasting process to achieve the desired flavor profile.

Sensory Evaluation

Sensory evaluation involves the use of the senses to evaluate the coffee’s characteristics, including flavor, aroma, body, and acidity. Flavor refers to the coffee’s taste, including notes of fruit, chocolate, or nuts. Aroma refers to the coffee’s smell, including notes of floral, herbal, or spicy. Body refers to the coffee’s texture, including notes of heavy, medium, or light. Acidity refers to the coffee’s brightness, including notes of sharp, snappy, or dull.

| Characteristic | Description |

|---|---|

| Flavor | The coffee's taste, including notes of fruit, chocolate, or nuts |

| Aroma | The coffee's smell, including notes of floral, herbal, or spicy |

| Body | The coffee's texture, including notes of heavy, medium, or light |

| Acidity | The coffee's brightness, including notes of sharp, snappy, or dull |