Auto Air Condition Repair

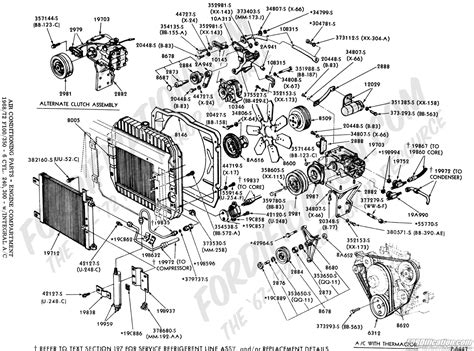

Automotive air conditioning repair is a specialized field that requires a thorough understanding of the complex systems involved in cooling and heating a vehicle's interior. With the increasing demand for comfort and convenience in modern vehicles, the air conditioning system has become an essential component, and its repair has become a crucial aspect of automotive maintenance. The automotive air conditioning system is designed to provide a comfortable temperature and humidity level inside the vehicle, regardless of the outside weather conditions. It consists of several key components, including the compressor, condenser, evaporator, and refrigerant, which work together to cool the air and distribute it throughout the vehicle.

Common Issues with Auto Air Conditioning Systems

There are several common issues that can affect the performance of an auto air conditioning system, including refrigerant leaks, clogged air filters, and faulty compressors. Refrigerant leaks are a common problem, as they can cause the system to lose its cooling capacity, leading to reduced performance and increased fuel consumption. Clogged air filters can also reduce the system’s performance, as they can restrict airflow and cause the system to work harder, leading to increased energy consumption. Faulty compressors can also cause problems, as they can fail to compress the refrigerant, leading to reduced cooling capacity and increased noise levels.

Diagnosing Auto Air Conditioning Problems

Diagnosing auto air conditioning problems requires a systematic approach, starting with a visual inspection of the system’s components and connections. The technician should check for signs of leaks, corrosion, or damage, and verify that the system is properly charged with refrigerant. The technician should also perform a series of tests, including a pressure test, to identify any leaks or blockages in the system. Additionally, the technician may use specialized equipment, such as a refrigerant leak detector, to identify the source of any leaks. Refrigerant leak detection is a critical step in diagnosing auto air conditioning problems, as it can help identify the source of the leak and prevent further damage to the system.

| Component | Description | Symptoms of Failure |

|---|---|---|

| Compressor | Responsible for compressing the refrigerant | Reduced cooling capacity, increased noise levels |

| Condenser | Responsible for cooling the refrigerant | Reduced cooling capacity, increased temperature |

| Evaporator | Responsible for cooling the air | Reduced cooling capacity, increased humidity |

Repairing Auto Air Conditioning Systems

Repairing an auto air conditioning system requires specialized tools and equipment, as well as a thorough understanding of the system’s components and operation. The repair process typically involves several steps, including refrigerant recovery, which involves removing the refrigerant from the system and storing it in a specialized container. The technician may also need to replace faulty components, such as the compressor or condenser, and recharge the system with new refrigerant. Refrigerant recharging is a critical step in the repair process, as it requires careful attention to the system’s specifications and operating conditions.

Preventative Maintenance for Auto Air Conditioning Systems

Preventative maintenance is essential for ensuring the longevity and performance of an auto air conditioning system. This includes regular inspections and cleaning of the system’s components, as well as refrigerant checks to ensure that the system is properly charged. The technician may also recommend system flushing, which involves removing debris and contaminants from the system to prevent corrosion and damage. By following a regular maintenance schedule, vehicle owners can help prevent problems and ensure that their auto air conditioning system continues to operate efficiently and effectively.

- Regular inspections and cleaning of the system's components

- Refrigerant checks to ensure that the system is properly charged

- System flushing to remove debris and contaminants

What are the most common causes of auto air conditioning problems?

+The most common causes of auto air conditioning problems include refrigerant leaks, clogged air filters, and faulty compressors. Refrigerant leaks can cause the system to lose its cooling capacity, while clogged air filters can restrict airflow and cause the system to work harder. Faulty compressors can fail to compress the refrigerant, leading to reduced cooling capacity and increased noise levels.

How often should I have my auto air conditioning system inspected and maintained?

+It's recommended to have your auto air conditioning system inspected and maintained at least once a year, or every 12,000 to 15,000 miles. Regular inspections and maintenance can help prevent problems and ensure that the system continues to operate efficiently and effectively.

In conclusion, auto air conditioning repair is a complex and specialized field that requires a thorough understanding of the system’s components and operation. By following a systematic approach to diagnosis and repair, technicians can identify and fix problems quickly and efficiently, helping to ensure that vehicle owners stay cool and comfortable on the road. Regular preventative maintenance is also essential for ensuring the longevity and performance of the system, and can help prevent problems and reduce the need for costly repairs.